Grieg Seafood is one of the world's biggest salmon producers and a world leading fish farming companies, with an annual production target of 100,000 tonnes gutted weight (in 2020). They were listed on the stock market in 2007 and today the company (all departments included) employ almost 1,000 people.

Behind their success is both craftsmanship, dedication, determination… and technology! Running a large modern fish farm is almost impossible without modern technology. This is especially true for land-based RAS facilities. Changes in water quality, a pump that does not work properly, a malfunction in a filter etc. can quickly create a situation that puts the entire stock at risk – in the worst cases causing mass die off. Often these dramatic events could have been prevented with a simple monitoring-alarm system.

Grieg Seafood

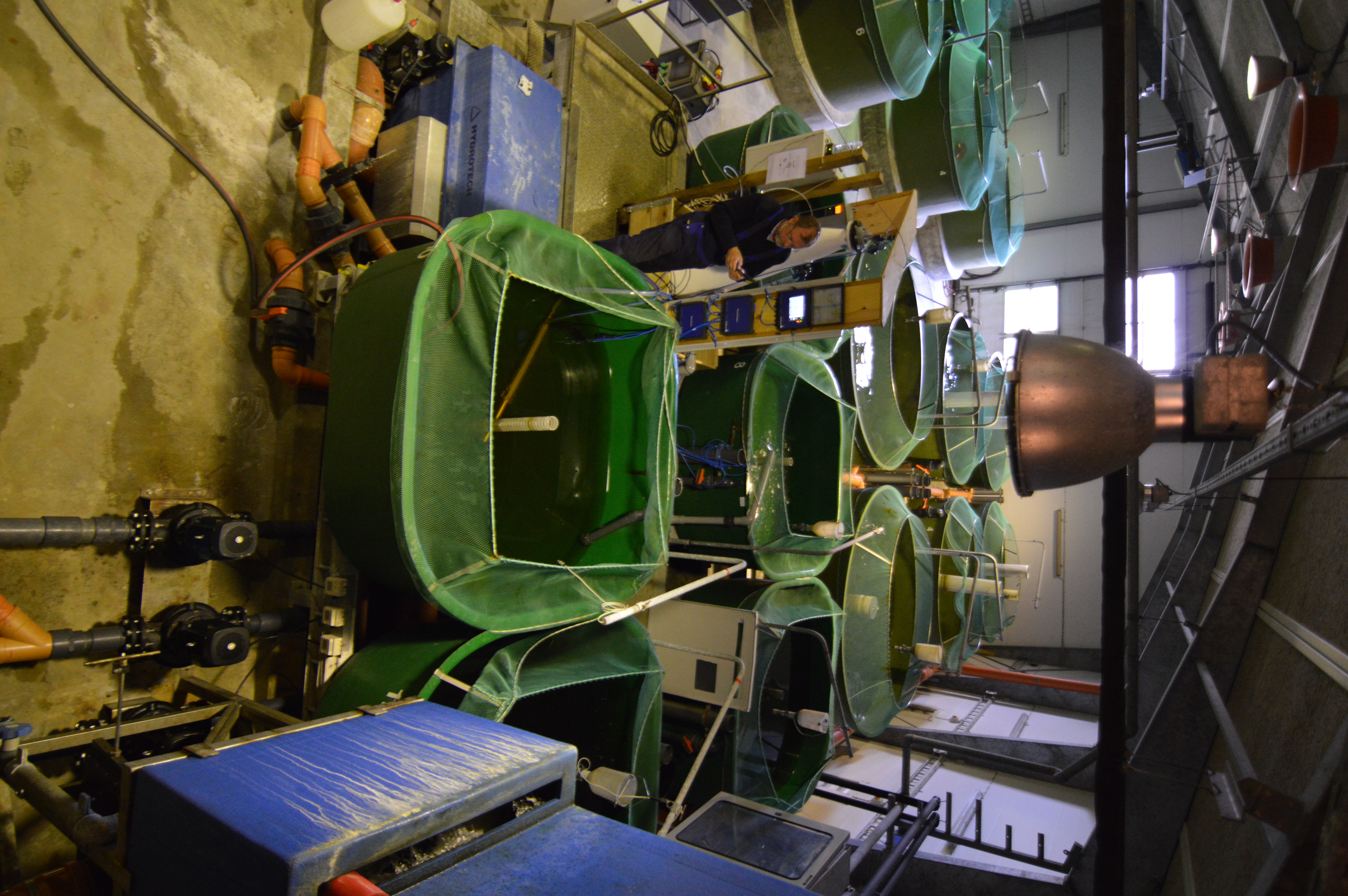

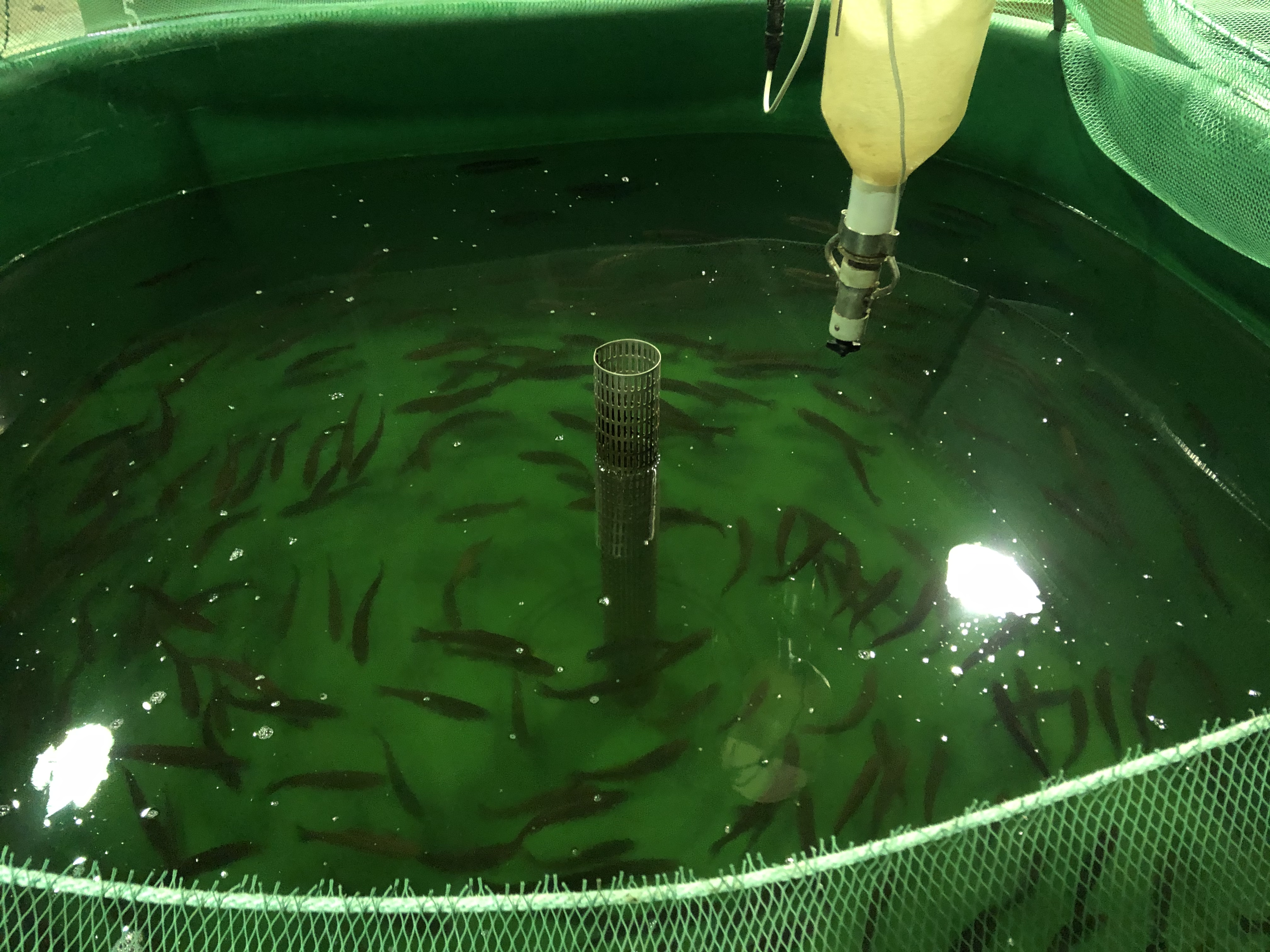

At Grieg seafood's smolt facility on Trosnavåg, Norway, nothing is left to chance. Everything is carefully monitored and the majority of the equipment on the facility is under automatic control. In case of pump failure, water level deviations, oxygen loss etc., they will get a notice within seconds. They use OxyGuard's Commander Pacific, and they are very happy with the system.

The manager, Atle Jøsang explains, 'We chose the Commander Pacific system for several reasons. First off, we have a good connection to the technicians at OxyGuard, and we knew that they would provide the service we needed. This is an important thing, especially during the start-up of a facility where changes happen all the time. These systems are, to a large extent, tailored to the specific facility and the distance between success and failure lies in the margins.'

Stand Alone

OxyGuard's Commander Pacific is a so-called 'stand-alone system'. Everything can be controlled and monitored from a central monitor with touch screen. The graphical interface allows the user to get a good overview of the entire farm including conditions in the individual tanks. Everything can be monitored directly from this main unit, or from a PC, smartphone, or tablet. From the touch screen, tank specific information on oxygen saturation, pH, water level etc. can be accessed simply by clicking the tank icon on the screen. A graduated alarm system indicated with colour codes gives a quick overview of the conditions on the farm and makes it easy to locate a problem before it gets serious. Alarm specification can be given on-the-go via text messages or email. The user can determine the set point for different alarms depending on the farm-specific needs.

The system is scalable, and the different addable units work like Lego to build out, rebuild, and rescale. Different units (boxes) have different input and output channels and everything with an electric current can be added. Add-on programs can be included for complete daylight control, feeding program, etc. According to Atle Jøsang the system is intuitive and easy to use so that operators rarely need to consult the manual (except for calibrations).

Besides the security they gain from this automatic control the system also saves them time. 'Keeping track of everything on a large modern RAS facility is complex and time consuming and mistakes happen often if there is no monitoring system in place. We have integrated the graduated alarm system to give us notice in case of small discrepancies and not only in case of red alerts. This gives us time to solve a challenge before it gets too serious'.

Another great advantage of the Commander Pacific system is the stability it brings to the fish environment. 'By using Commander Pacific, we create a stable growing environment for the fish where all water quality parameters are kept within the optimal limits for the salmon,' says Atle Jøsang.

Security and stability

More than once, the commander pacific system has saved the facility from problems.

'There are much to remember in the daily management of a facility like ours and we use the alarm system to make sure these unavoidable events will not lead to any dramatic events. The system gives us both stability and security', adds Jøsang.

Monitoring and control gives stability and security. By monitoring, data becomes available for more advanced analysis. The amount of data that drives the development of aquaculture is enormous. Big scale logistics, consumer preferences, environmental challenges, legislation and resource availability and, on a smaller scale, all the data that controls the local production on the individual farms, such as feed quality, water temperature, water matrix conditions, stock density, etc. are just a few of the aspects that need measuring continually.

Even though we can measure and control these parameters, the complexity of the entire system is incomprehensible for our traditional analytical tools. The data is both interlinked and correlated to other parameters. If we change one variable, the optimal threshold for another might change also. It is impossible to conduct the best possible practises based on the complexity of these feedback systems without modern Big Data analytical tools. OxyGuard's Cobália is such a tool and it has just been released. When used alongside the Commander Pacific system, a fish farm can achieve top of the class performance. Cobália adds the extra layer of digitalisation and optimisation.

Automation, monitoring and digitalisation bring a fish farm up to date with the production methodology used in the rest of the food sector, benefiting the entire value chain of fish and seafood. The traceability that comes along with the digitalisation, builds customer trust in the products, therefore securing the sector for the future.

Commander Pacific statistics:

- Produced by OxyGuard International

- Stand-alone monitoring and control system for aquaculture

- Suitable for both small and big fish farms, RAS, sea cages and fish transport

- Multi-channel and multi-parametric

- Wireless and wired

- Digital and analogue in-output (everything with an electric current can be added)

- Modular: Can be used like Lego to build out, rebuild, and rescale.

Grieg Seafood Rogaland statistics:

- Number of employees: 150 in the region

- Production Capacity: 24,000 tonnes gutted weight

- Certification: Global Gap

- Licenses: Two smolt licenses and 20 grow out licenses

- Trosnavåg smolt facility is part of Grieg Seafood Rogalaand (GSFR). GSFR is divided into four divisions, namely broodstock, hatchery and grow-out

- Atle Jøsang is the Daily Manager at the Torsnavåg RAS facility for smolt.